DISCOVER INLAND LAKES

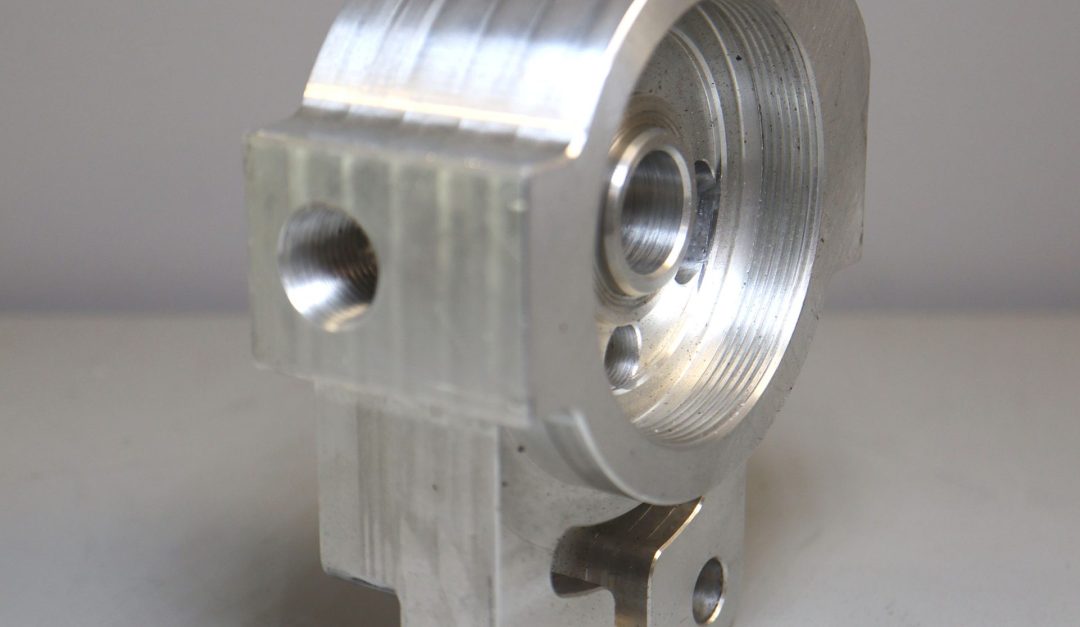

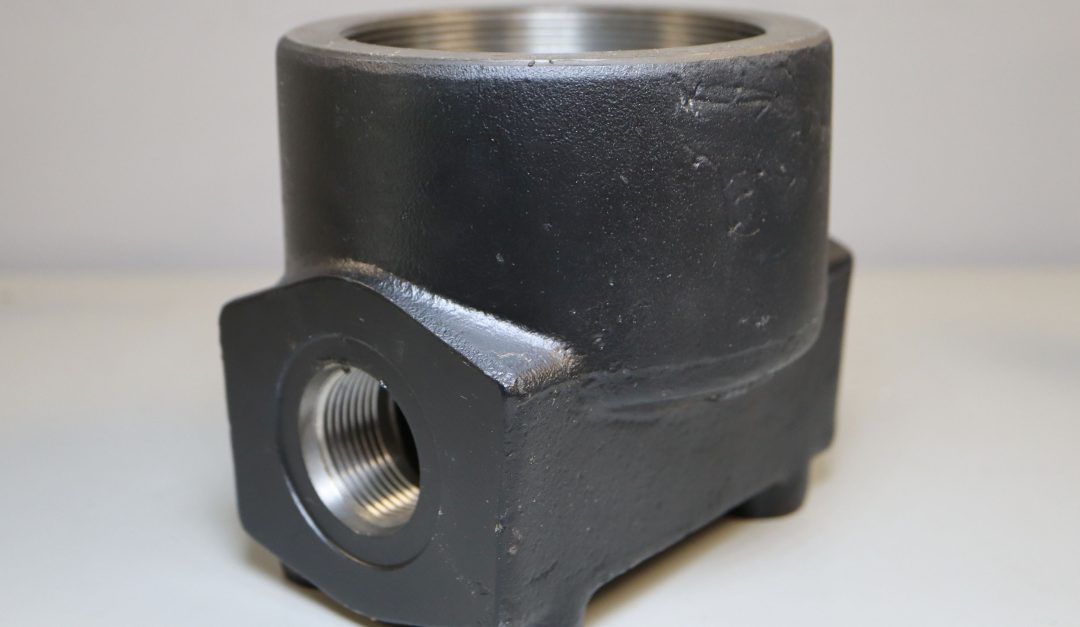

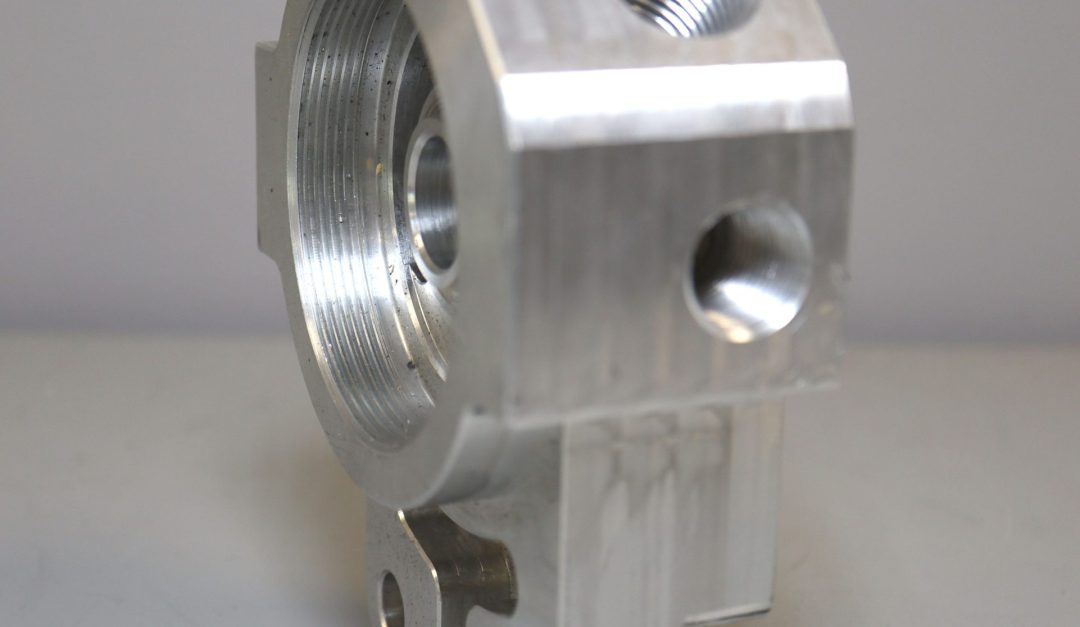

Inland Lakes Machine is dedicated to offering our customers an uncomplicated buying experience by supplying them with precision machined parts complete per their specifications.

We manufacture precision machined parts at our 50,000 sq ft facility conveniently located in Cadillac, MI since 1945. The layout of our production area promotes efficient work flow and material handling, while our employees dedication and years of experience help us produce a wide variety of machined components. These efficiencies and our commitment to purchasing the newest machines and technologies, allows us to process parts more efficiently and cut costs and lead times for our customers.

We supply a variety of machined components by processing materials over machines in one of our various departments:

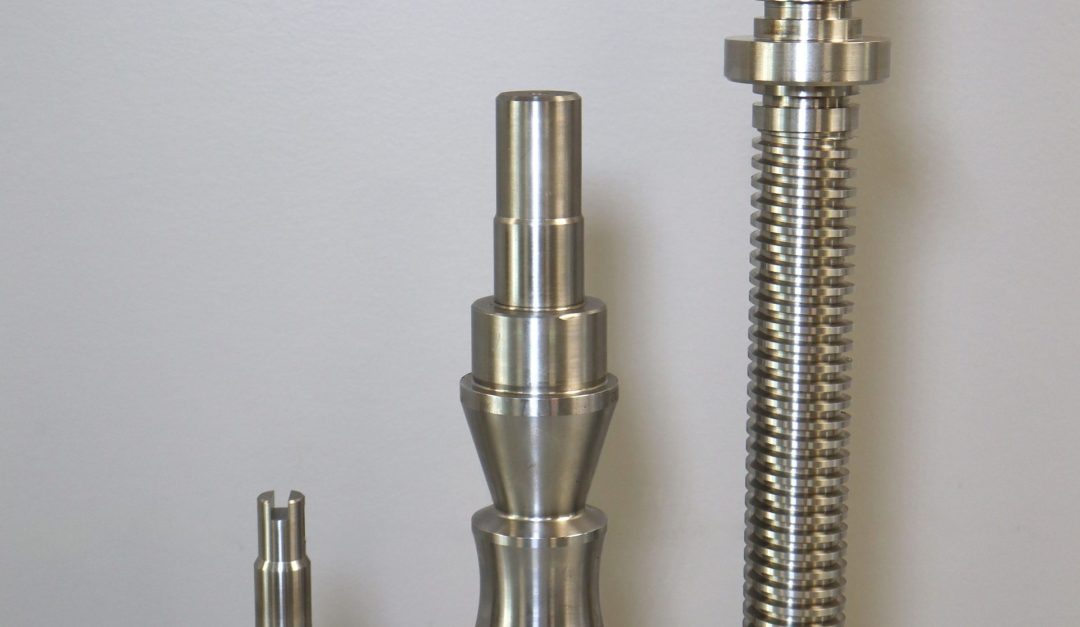

* Multi-axis CNC Lathes produce turned parts up to 17 Inches in diameter

* Multi-axis CNC Vertical and Horizontal Mills run multiple operations in one set-up.

* Multi-axis Swiss machining for precision parts run complete in one operation.

* Complete Screw machine department for higher volume runs

* Quality Assurance from order entry to post production

* A full line of secondary operations

* Light assembly

Inland Lakes commitment to providing our customers with world-class manufacturing is demonstrated by our understanding of client expectations and then delivering and even improving upon them. Customers know they can rely on Inland Lakes because we stand behind our products 100%. Our employees have the resources, experience and craftsmanship to meet all of our customers machined product needs time after time, which is why some of our customers have been with us since our founding in 1945.

Contact us for information on machining CNC precision parts

SERVICES

CNC Turning Services

Inland Lakes delivers value-added consulting and CNC machining services for our customers. Our commitment to making the highest quality machined products begins with understanding our customers operations and the manufacturing process behind their final component assembly. We have the capabilities to achieve competitively priced CNC machining of almost any part.

Secondary and Finishing Operations

An array of support equipment is available for use to meet customer design engineering and CNC machining needs.

* Broaching

* Drilling

* Grinding

* Milling

* Slotting

* Tapping

* Turning

* Assembly

* Lasering/Part Marking

Don’t hesitate to contact us about our CNC machining capabilities!

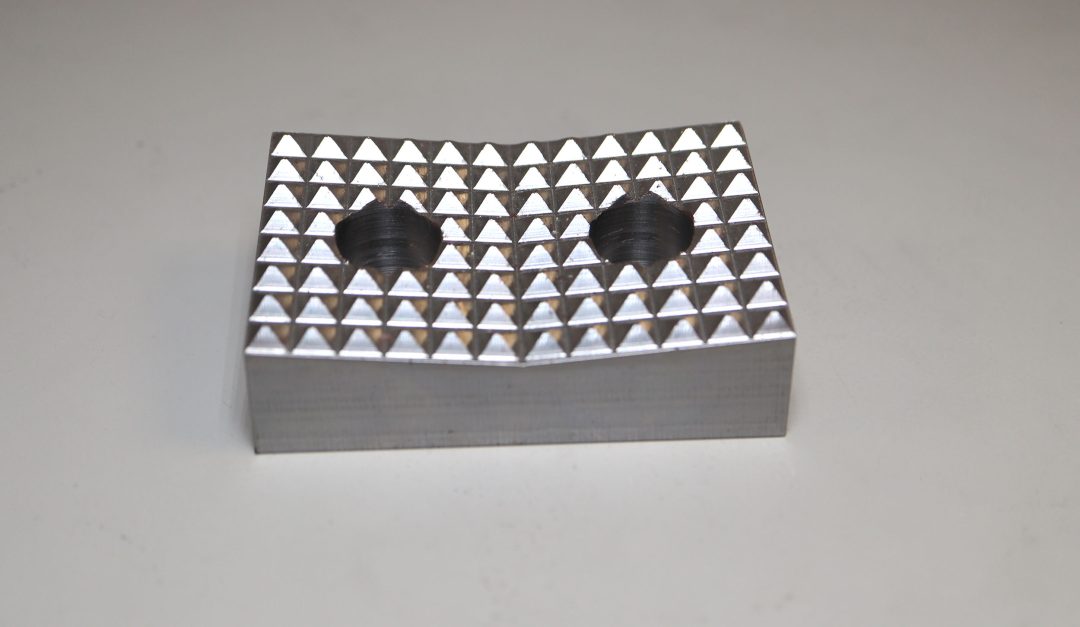

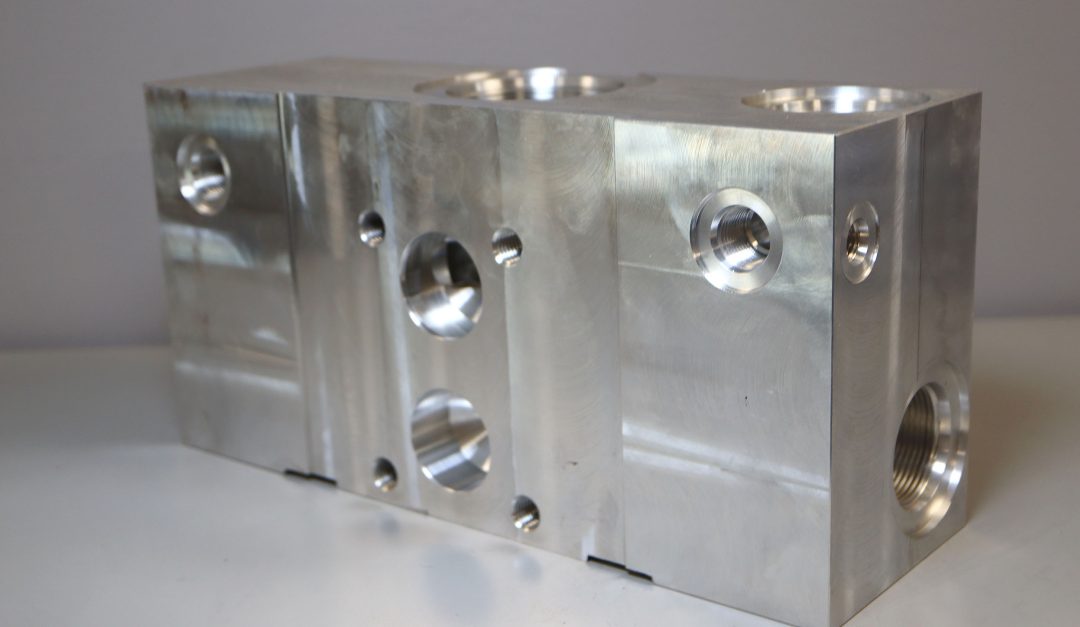

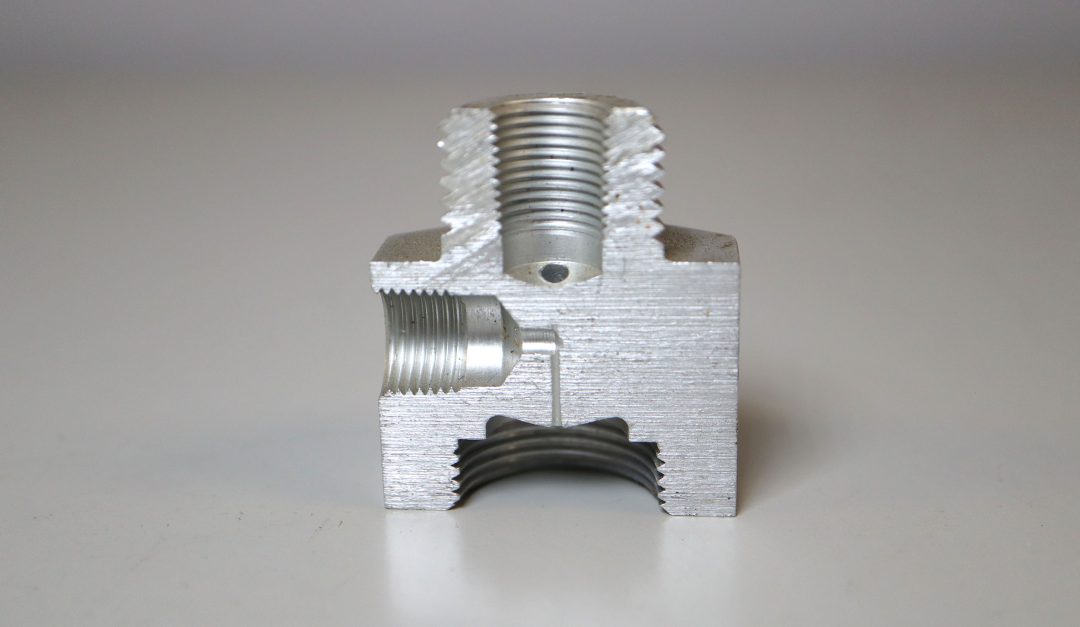

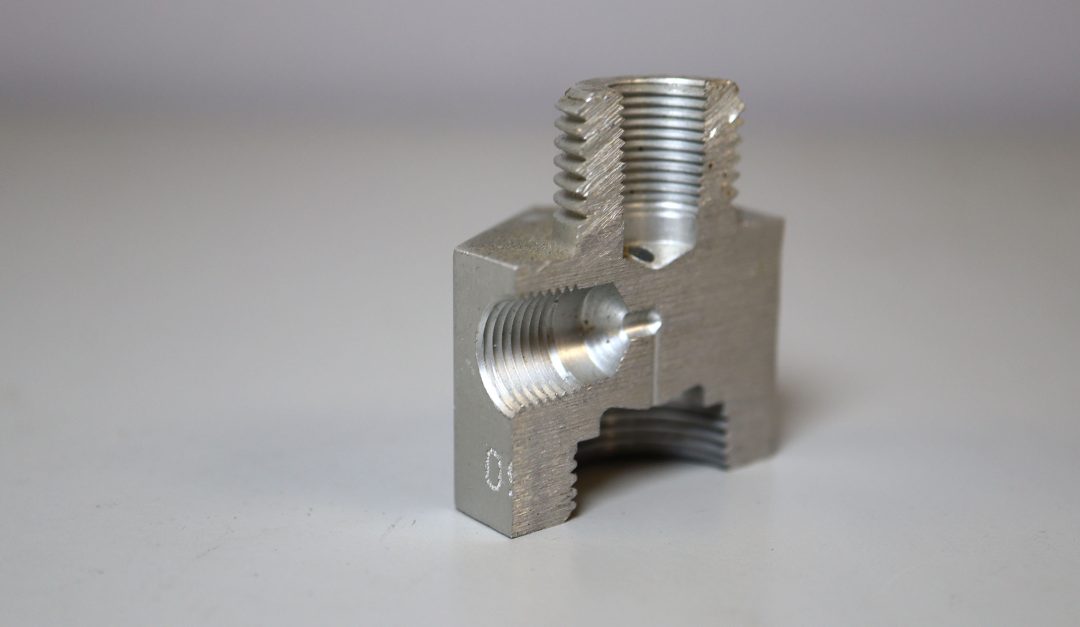

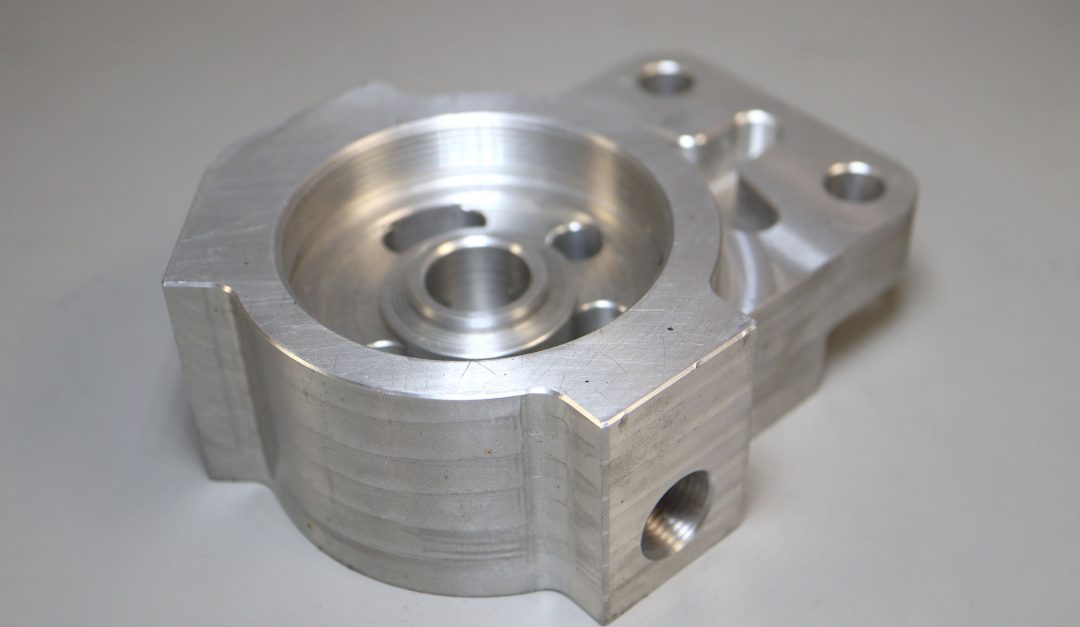

CNC Precision Milling Services

We operate multi-axis CNC Milling machines to accomplish precise, high-speed milling, drilling, tapping and turning. Our machinists take advantage of CAD/CAM software to visualize the finished part during design and to program the milling machine how the part will be machined to ensure part quality and accuracy.

Precision CNC Milling Machines

- Use computer controlled accuracy to achieve consistancy of even the most complex parts throughout a production run

- 5 axis milling allows us to keep costs low to our customers by reducing the number of operations required

- Offer manufacturing repeatability of precision parts for low to high volume runs

- Handle a variety of materials including ferrous and non-ferrous metals, plastics and other materials

Our experienced CNC machinists understand manufacturing and the pressures our customers face to keep their inventories down while increasing productivity. Whether the job calls for being flexible on design changes, adapting to specific production needs, or anticipating inventory fluctuations, we work in close partnership with every customer to achieve quality and precision at a competitive price.

We look forward to hearing from you, contact us today about our CNC machining services!

Swiss Machining Services

Multi-axis, multi-process Swiss machining allows us to serve a market for machined products where complicated parts require complex tolerances, multiple operations all in one set-up. Our customers see the benefits of the Swiss machines in faster turnaround times, lower job costs and superior quality parts.

Multi-axis

Complex CNC precision parts are completed in their entirety in a single operation on our Swiss multi-axis machines. This increases productivity while reducing potential for damage through multiple operations and potential loss of parts.

Multi-process

Our Swiss machines perform production CNC machining operations such as milling, drilling, boring and tapping. This results in a substantial reduction of the aggregate time required to machine the part and an increase in accuracy and repeatability.

Quick Setup Time

Quick setup times mean reduced setup costs and faster job turnaround. Short-notice orders can be easily accommodated.

Chip Evacuation

High pressure coolant systems allow the evacuation of tough stringy chips that otherwise interfere with operations. This boosts machine productivity and adds to the superior quality of the finished part.

Bar Feeders

Magazine bar loaders for 12’ bars are on all our Swiss machines. This automatic bar feeder capability increases the efficiency and cost savings of part runs.

Capacities

Our Swiss machine bar stock capacity ranges from .125 to 1.250” diameter.

Production Runs

Our Swiss Machining manufactures production CNC Machining runs of complex precision parts with uniform high quality from 250 pieces and up.

Our CNC staff would be happy to answer your Swiss machining questions. Contact us today!

Screw Machining Services

Screw machining is one of the primary services that we provide. We continually improve our processes and push towards automation in this department. These process improvements, along with enhanced capabilities through automation, have fueled our growth in this area. Our customer base is diverse with applications ranging from automotive to electronic sensors, fluid control, food service, heavy duty trucks, material handling, military, and pneumatics

Browne & Sharpes

Our Browne & Sharpes process jobs in volumes of 100 to 5,000 pcs and in sizes ranging from 1/16” to 2-1/4” diameter.

New Britans

Our New Britans process jobs in volumes of 2,000 to 250,000 pcs and in sizes ranging from 3/4” to 2-1/4” diameter.

Davenports

Our Davenports handle volumes from 2,000 pcs to 500,000 pcs and sizes ranging from 1/8” to 1” diameter.

INDUSTRIES SERVED

Inland Lakes Machine is committed to excellence in the quality and reliability of our service and to providing our customers with the product they need when they need it. We are a diverse shop and proudly serve various industries from automotive to food service.

AEROSPACE

AUTOMOTIVE

CONSTRUCTION

ELECTRIC SENSORS

FILTRATION

FLUID CONTROL

FOOD SERVICE

HEAVY EQUIPMENT

HYDRAULICS

MATERIAL HANDLING

MILITARY

PNEUMATICS

RECREATION & SPORT

SANITATION

TOOL & DIE

TRUCKING AND TRANPORTATION

At Inland Lakes we machine a variety of materials such as aluminum, brass, bronze, copper, plastic, free machining steel, alloy steel, stainless steel, and composites into the parts and products our customers require.

Contact us today about machining for your industry!

QUALITY ASSURANCE

Our quality assurance covers all aspects of product quality, from order entry through post-production. Continuous monitoring and continuous improvement hold part costs down, improve production turnaround time and ultimately are realized in customer satisfaction.

ISO Certified

The Inland Lakes quality management system is ISO certified to the current standard. Our quality management system complies with all of the standard’s strict demands including first piece inspection, in process inspection, document retention and internal auditing of documented procedures.

Reporting / Traceability

Complete first article reports and initial sampling inspection reports are standard with every new job we perform. Every job is traceable so our customers benefit from fast issue resolution.

PPAP Final Inspection and Kanban Ship to Stock

We utilize a recognized parts approval process and the latest technology for our inspection procedures and are an approved supplier for many customers that rely on us to ship directly to their stock.

Measuring Equipment

Our experienced quality assurance personnel have the latest technology available to perform all needed measurements of our machined parts. Our measuring equipment used in Quality Assurance is certified to NIST.

* Attribute Gauges

* Coordinate Measuring Machines

* Flatness Measurement Systems

* Hardness Testers

* Laser Measurement System

* Micrometers

* Optical Comparators

* Profilometer Surface Roughness Measurement Systems

* Roundness Measurement Systems

* Thread Measuring Gauges

MACHINERY LIST

LATHE DEPARTMENT

Mazak Quick Turn 20 – 10” chuck x 2

Star SR-20R Swiss Lathe w/ 12′ bar feeder

Star 32J Swiss Lathe w/12′ bar feeder x 4

Star 16 Type C Swiss Lathe w/12′ bar feeder

Mazak Quick Turn Ez12 – 12” chuck x 2

Haas St30 – 12” chuck x 2

Mazak Quick Turn Nexus 100 – 8” chuck x 5

Muratec w/gantry loader & dual 6” chucks

Puma 240M – 10” chuck

Puma 2500 LSY – 10” chuck w/6” sub & live tooling x 2

Mazak Quick Turn Nexus 250M – 10” chuck

Mazak Quick Turn 20 – 10” chuck x 6

Mazak QT Smart 350 – 12” chuck x 2

Mazak QT Smart 250 – 10” chuck x 4

Mazak QT Smart 200M – 8” chuck

Mazak QT Nexus 250-2 – 10” chuck x 6

Mazak QT nexus 200 – 8” chuck w/live tooling x 2

Mazak QT Nexus 250 MSY – 10” chuck

Haas ST25 – 10” chuck x 2

Haas St25 with live tooling & robot – 10” chuck x 2

Mazak QT 6T – 5” chuck

Puma 240M – 10” chuck

Mazak QT 640T – 12” chuck

Mazak 28N – 10” chuck x 3

Mazak Quick Turn 10 – 6” chuck x 2

Okuma Captain – L470 10” chuck

New Britian 6 Spindle – x2

Brown & Sharpe Screw Machine – x 9

MILLING DEPARTMENT

Haas UMC 500 5-Axis x 5

Haas VF 2SS x 3

Haas Super Mini Mill x 7

Fanuc RoboDrill

Hass VF 4SS w/pallet changer x 2

Mazak VTC 200B

Mazak PFH-4800

Mazak U-4800

Mazak HTC-400

SECONDARY SUPPORT MACHINES

Boss FM Laser

ProPen Parts Engraver x 2

Centerless Grinder

Bridgeport Straddle Mill

Drill Press x 8

Spartan Saw x 4

Ultrasonic Parts Washer

Multi Spindle Deca Drill

Surface Grinder

GALLERY

Click on image to view full size

CONTACT US

ABOUT US

Inland Lakes Machine remains dedicated to offering our customers an uncomplicated buying experience by supplying them with precision machined parts complete per their specifications.

OUR ADDRESS

Inland Lakes Machine

314 Haynes Street

Cadillac, MI 49601

DIRECTIONS

GET IN TOUCH

© Copyright, 2025 All Rights Reserved